Upgraded and completely rebuilt 4 axis Servo powered Fellows 10-2, 10-4, 20-4. Retrofit Customization can be ordered to meet your companies budget & specific needs.

Capacities U.S Metric  • Maximum Pitch Diameter (External) .................10" 254 mm • Maximum Pitch Diameter (Internal)...................10" 254 mm • Maximum Face Width, External/Internal............4" 102 mm • Maximum Diametral Pitch, Spur.........................4 6 MOD • Maximum Diametral Pitch, Helical......................5 5 MOD • Maximum Face Width 10-2.................................2" 51 mm • Maximum Face Width 10-4.................................4" 102 mm • Maximum Helix Angle (Using 5" Cutter)...............45 deg. 45 deg. • Maximum OD of Fixture.......................................19" 483 mm • Bore Through Work Spindle................................5.875" 149.225 mm • Cutter Spindle Diameter......................................3.543" 90 mm • Distance Between Work Table and Cutter Head...13" 330 mm • Height of Machine.................................................103" 2616 mm • Length of Machine.................................................132" 3353 mm • Width of Machine..................................................70" 1778 mm • Net Weight of Machine (approx.)...........................12,000 lbs. 5443 kg • 480 Vac 60 Amp |

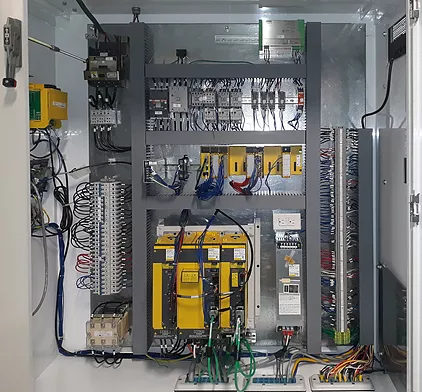

STANDARD EQUIPMENT & FEATURES  • FANUC Oi-MF Control • FANUC Servo Main Drive Motor • Hydro-static Cutter Spindle Bushing • No change gears required for B & C Axis (FANUC Servo Motors) set up is fully programmable • Z Axis FANUC Servo Ball Screw • Attached Electrical Cabinet & Hydraulic Tank • Air conditioned Electrical Cabinet • Work Spindle Top Plate with T slots every 90 degrees • Centralized Automatic Lubrication System • Way Lube Pump • Automatic Lube Filtering System  • Separate Pulse Lubrication System for Ways and Ball Screw • Coolant Sump in base • Removable chip basket • Standard Straight Spur Guide • Crowning and Taper feature via back off cam • Cutter Positioning • 3" riser. • Full splash guard with automatic door lock • Hydraulic clamping • Hydro-static Cutter Spindle Bushing • Inch & mm units of measurement • Work light • Tailstock prep for future Tailstock application • Prepped for a conveyer system • Cutter Spindle cooled by oil (not coolant) |

CNC FUNCTIONS  • 50 - 1000 Strokes Per Minute • Internal & External gear cutting • B, C, & Z Load Positioning • Gear, Gear with Laser, Slot, & Sector cutting modes • Cutter Advance (Cutter Shift) • Automatic Homing of all Axes simultaneously • Auto Load Positioning for the Work Table & the Cutter Spindle • Cutter Spindle Rapid Rotation • Work Table Rapid Rotation • User friendly set up screens • One to four cut selection • Each cut has individual parameters of depth of cut, infeed rate, stroking speed, rotational feed rate, and degree of work rotation • Setups can be stored in nonvolatile memory using a setup number between 1-999 • Recut mode that skips roughing cuts and directs the machine to the final cut • Manual Pulse Generator • Work clamping sequence options of Clamp Up or Clamp Down • Cycle & Shift counter • Three Spindle Stroking stop positions for easy set up • Normal & Service Operation modes • Operator Lock Out Mode |

OPTIONAL EQUIPMENT

• Automatic chip conveyor • Elevating mechanism for raising and lowering fixture up to 3.125" (79.38 mm) for recessed internal gears or automatic loading • High speed worm • Robot interface • Magnetic filter • Additional optional equipment is available upon request |